Printed Circuit Board (PCB) Material Selection Guide

A rigid-flex printed circuit board (PCB) is a printed circuit board made with rigid and flexible substrates. The resulting component combines aspects of hardboards and flexible circuits, with some rigid sections and some flexible sections. This unique design provides support to the areas that need it and enables flexing or folding in the areas that require it.

There are many benefits to using rigid-flex PCBs over other PCB options. For example:

Ensuring your rigid-flex PCB solution fully meets your unique needs necessitates a careful assessment of the options available during the initial design phase. There are three main types of rigid-flex PCBs, each of which has distinct characteristics that make it suitable for different applications.

Applications for rigid-flex PCBs can be classified into two broad types:

Both flex-to-install and dynamic-flex applications are found in virtually every industry. Examples of typical uses for rigid-flex PCBs include:

Both flex-to-install and dynamic-flex applications are found in virtually every industry. Examples of typical uses for rigid-flex PCBs include:

Want to learn more about rigid-flex printed circuit boards? Ask the experts at Redstar Worldwide. As an experienced supplier of rigid-flex PCB solutions, we can answer and address any questions or concerns you may have about these components. Additionally, if you decide rigid-flex PCBs are right for your needs, we have the knowledge and skills to help you with everything from finalizing your design to compiling documentation for the manufacturer so you can successfully bring your product to market. Request a quote to start your order.

A printed circuit board (PCB) is a multi-layered electrical circuit that connects electronic components through the use of conductive tracks etched into one or more layers of copper foil on a non-conductive substrate material. PCBs are smaller, lighter, and more efficient than their traditional wired counterparts, which makes them ideal for use in increasingly complex and miniaturized technology. They are also easier to manufacture, install, and maintain, for more cost-effective and reliable operation.

PCB manufacturing is largely automated, which makes it extremely efficient for manufacturing even highly complex boards with extreme precision. Although all PCBs operate under similar principles and contain similar components, each type of PCB has unique benefits for specific applications.

PCBs are available in a wide variety of designs, the most common of which are flexible, rigid, and rigid-flex. These PCB designs are categorized based on the fundamental stiffness of the PCB substrate, and each offers distinct advantages for particular applications.

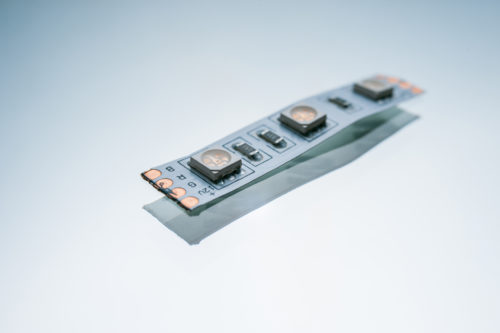

. Flexible PCB

. Flexible PCBFlexible PCBs are characterized by their ability to bend, fold, and crease in order to fit into small or irregularly shaped voids. Rather than manufacturing the product to fit the PCB, a flex PCB can be made to fit within the design. Flexible PCB board materials also tend to be lighter, stronger, and more heat-resistant than rigid PCB materials.

Rigid PCBs are characterized by the unyielding nature of their substrate material. While they can be less expensive to fabricate than flexible PCBs, rigid PCBs do not have the same level of versatility. Rigid PCBs exhibit a high degree of durability and strength, which makes them ideal for applications in harsh or extreme conditions, where space is not a concern.

Rigid-Flex PCBs are multi-layered circuit boards that combine the stability of rigid circuit board designs with a more flexible substrate material. This allows manufacturers a greater level of control over product design while ensuring durable circuit connections. The flexible substrate allows rigid-flex PCBs to fit into unusual geometries and tight spaces common in automotive, aerospace, and medical equipment.

Redstar Worldwide is a preeminent supplier of superior quality PCB solutions for our customers. Our relationships with reputable manufacturers across the globe allow us to provide the highest quality PCBs within a competitive price range. Our services and capabilities include:

Our flexible and rigid-flex PCBs are designed for the highest level of versatility and flexibility. With a flexible substrate material, you can fit our products into a variety of unusual configurations, and their combination of flexible and solid components can be configured to meet the needs of your application.

. Metal Core Printed Circuit Board Solutions

. Metal Core Printed Circuit Board SolutionsOur metal core PCBs are printed on a metal base material laminated with a layer of dielectric polymer. This allows for extremely high processing without the risk of overheating.

Our selection of high-density interconnect (HDI) PCBs offer a convenient, compact design. They feature efficiently placed smaller components, increasing the number of circuits that can be included. The close proximity of circuit board components allows for faster signal travel, minimizing delays and reducing signal loss.

Redstar is pleased to offer quick-turn prototyping for all types of PCBs. Our prototyping services include a comprehensive manufacturability review and a series of quality checks to ensure optimal PCB functionality with a quick turnaround.

Our expert team of application engineers works directly with you to ensure that your PCB design and manufacturing process is both cost-efficient and effective.

At Redstar Worldwide, we ensure top-quality PCB solutions. We will work with you to find the best PCB suited to your price, quality, and application requirements. With both domestic and international suppliers, we deliver products quickly and accurately, creating a smooth, worry-free ordering experience. To learn more about our PCB services, contact us or request a quote today.